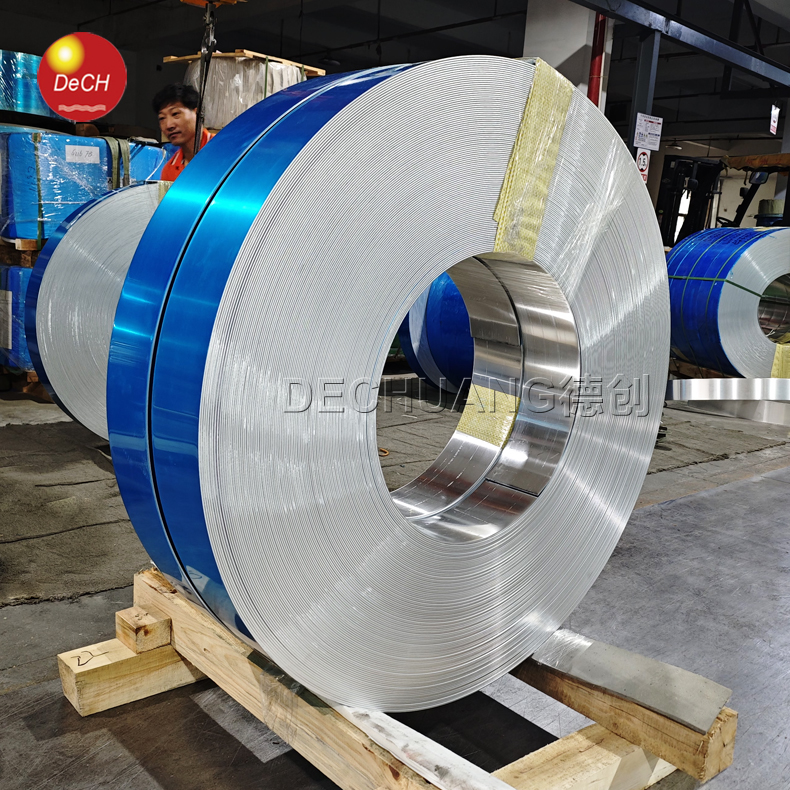

Aluminum Strip

Show

Specifications Applications

| Category | Main Alloy | Condition | Thickness (mm) | Application |

|---|---|---|---|---|

| 1xxx | 1050, 1060, 1070, 1100, 1145 | O, F, H12, H14, H16, H18, H22, H24 | 0.1–20 | Lithium battery soft connections, lighting, cosmetic caps, bottle caps, capacitor shells, mirror panels, curtain wall panels, aluminum-plastic strips |

| 1060, 1070, 1080, 1100, 1235, 1235D | O, H14, H18 | 0.0055–0.5 | Lithium batteries, sodium batteries, electronic capacitors, food packaging | |

| 3xxx | 3003, 3004, 3005, 3104, 3105 | O, H14, H16, H18, H22, H24, H26 | 0.2–6.0 | Battery case/top cover, heat exchanger composite material, brazing composite material, cabinets, curtain walls, ceilings, curtains, vacuum glass insulation, anti-corrosion insulation |

| 3003 | H18 | 0.02–0.05 | Electronic capacitors | |

| 4xxx | 4343, 4004, 4045, 4047, 4104 | O, H14, H16, H24 | 0.08–0.2 | Heat exchangers, PCB boards |

| 5xxx | 5005, 5052, 5252, 5182, 5083, 5754, 5L52 | O, F, H14, H19, H24, H26, H32, H34, H36, H38, H111, H112 | 0.3–400 | Anodizing, deep drawing, mobile phone/laptop shells, PACK separators, pressure vessels, air separation equipment, lamp holders, automotive interior/structural parts, curtains |

| 6xxx | 6061, 6063, 6111, 6009 | F, T6 | 0.3–200 | Instrument panels, molds |

| 8xxx | 8011, 8021, 8079 | O, H24 | 0.0055–0.03 | Pouch battery aluminum-plastic film, pharmaceutical, food, air conditioning |

Chemical Composition

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | — | 0.05 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.04 | 0.05 | 0.03 | — | 0.04 | 0.03 | 99.7 |

| 1100 | Si + Fe ≤ 1.0 | — | 0.05–0.2 | 0.05 | — | — | 0.1 | — | 99 |

| 2024 | 0.5 | 0.5 | 3.8–4.9 | 0.3–0.9 | 1.2–1.8 | 0.1 | 0.25 | 0.15 | Balance |

| 3003 | 0.6 | 0.7 | 0.05–0.2 | 1.0–1.5 | — | — | 0.1 | — | Balance |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50–1.1 | 0.1 | 0.25 | — | Balance |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2–2.8 | 0.15–0.35 | 0.1 | — | Balance |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4–1.0 | 4.0–4.9 | 0.05–0.25 | 0.25 | 0.15 | Balance |

| 6061 | 0.4–0.8 | 0.7 | 0.15–0.4 | 0.15 | 0.8–1.2 | 0.04–0.35 | 0.25 | 0.15 | Balance |

| 6063 | 0.2–0.6 | 0.35 | ≤0.1 | ≤0.1 | 0.45–0.9 | 0.1 | 0.1 | 0.1 | Balance |

| 7075 | 0.4 | 0.5 | 1.2–2 | 0.3 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | 0.2 | Balance |

| 8011 | 0.5–0.9 | 0.6–1.0 | ≤0.1 | — | — | — | 0.1 | — | Balance |

Physical Properties

| Grade | Temper | Brinell Hardness (HB) | Tensile Strength (σb, MPa) | Yield Strength (σ0.2, MPa) | Elongation (El, %) |

|---|---|---|---|---|---|

| 1050 | O | 20 | 85 | 30 | 35 |

| H14 | 34 | 110 | 50 | 15 | |

| H16 | 42 | 130 | 60 | 10 | |

| H18 | 48 | 150 | 65 | 7 | |

| 1060 | O | 22 | 90 | 35 | 30 |

| H12 | 28 | 110 | 50 | 20 | |

| H14 | 34 | 120 | 55 | 15 | |

| H16 | 38 | 130 | 60 | 10 | |

| H18 | 45 | 140 | 65 | 8 | |

| 1100 | O | 19 | 90 | 35 | 35 |

| H12 | 28 | 110 | 50 | 20 | |

| H14 | 34 | 120 | 55 | 15 | |

| H16 | 38 | 130 | 60 | 10 | |

| H18 | 45 | 140 | 65 | 8 | |

| 2024 | O | 60 | 200 | 90 | 20 |

| T3 | 120 | 470 | 325 | 20 | |

| T4 | 120 | 460 | 320 | 19 | |

| T351 | 130 | 470 | 325 | 20 | |

| 3003 | O | 28 | 100 | 35 | 30 |

| H14 | 42 | 160 | 130 | 8.3 | |

| H18 | 56 | 210 | 180 | 4.5 | |

| 5052 | O | 47 | 193 | 89.6 | 25 |

| H32 | 60 | 210 | 160 | 12 | |

| H34 | 65 | 230 | 170 | 10 | |

| H36 | 70 | 250 | 180 | 8 | |

| H38 | 75 | 270 | 190 | 6 | |

| H112 | 60 | 200 | 89 | 9.5 | |

| 5083 | O | 75 | 275 | 145 | 20 |

| H111 | 75 | 300 | 150 | 13 | |

| H112 | 65 | 310 | 210 | 16 | |

| H116 | 85 | 320 | 228 | 12 | |

| 6061 | O | 30 | 130 | 55 | 25 |

| T4 | 65 | 240 | 145 | 20 | |

| T6 | 95 | 310 | 275 | 17 | |

| T651 | 100 | 320 | 280 | 15 | |

| T6511 | 102 | 330 | 285 | 14 | |

| 6063 | O | 25 | 130 | 50 | 25 |

| T4 | 60 | 190 | 110 | 21 | |

| T5 | 70 | 240 | 150 | 12 | |

| T6 | 75 | 250 | 200 | 10 | |

| 7075 | O | 60 | 200 | 100 | 20 |

| T6 | 150 | 560 | 480 | 11 | |

| T651 | 155 | 570 | 490 | 10 | |

| T73 | 140 | 505 | 435 | 13 | |

| T7351 | 145 | 515 | 440 | 12 | |

| 8011 | O | 18 | 90 | 35 | 35 |

| H14 | 30 | 120 | 60 | 10 | |

| H18 | 45 | 150 | 100 | 5 |

厚度公差

厚度公差

| 厚度 Thickness (mm) |

公称宽度 < 600mm Nominal Width < 600mm |

600mm ≤ 公称宽度 < 1560mm 600mm ≤ Nominal Width < 1560mm |

||||

|---|---|---|---|---|---|---|

| JIS G4305 | ASTM 240 | 我司标准 | JIS G4305 | ASTM 240 | 我司标准 | |

| 0.1 ≤ t < 0.2 | ±0.02 | ±0.015 | ±0.01 | / | / | / |

| 0.2 ≤ t < 0.3 | ±0.025 | ±0.02 | ±0.01 | ±0.038 | ±0.038 | ±0.015 |

| 0.3 ≤ t < 0.4 | ±0.03 | ±0.025 | ±0.015 | ±0.04 | ±0.04 | ±0.015 |

| 0.4 ≤ t < 0.5 | ±0.04 | ±0.03 | ±0.015 | ±0.04 | ±0.04 | ±0.02 |

| 0.5 ≤ t < 0.6 | ±0.04 | ±0.03 | ±0.015 | ±0.04 | ±0.04 | ±0.02 |

| 0.6 ≤ t < 0.7 | ±0.045 | ±0.035 | ±0.015 | ±0.05 | ±0.05 | ±0.02 |

| 0.7 ≤ t < 0.8 | ±0.045 | ±0.035 | ±0.015 | ±0.05 | ±0.05 | ±0.02 |

| 0.8 ≤ t < 0.9 | ±0.05 | ±0.035 | ±0.02 | ±0.06 | ±0.06 | ±0.025 |

| 0.9 ≤ t < 1.0 | ±0.05 | ±0.035 | ±0.02 | ±0.06 | ±0.06 | ±0.025 |

| 1.0 ≤ t < 1.5 | ±0.06 | ±0.04 | ±0.025 | ±0.07 | ±0.07 | ±0.03 |

| 1.5 ≤ t < 2.0 | ±0.07 | ±0.04 | ±0.03 | ±0.08 | ±0.08 | ±0.035 |

© 2025 Dongguan Dechuang Hardware Co., Ltd. All Rights Reserved. ICP No. 2020103562

Dongguan Dechuang Hardware Co., Ltd.

Phone: +86-769-81888566

Mobile (WhatsApp): +86-13332617868 (Jane) / +86-17620152277 (Eric)

Email: hcy518@163.com (Jane) / sale2@dgdechuang.com (Eric)

Phone: +86-769-81888566

Mobile (WhatsApp): +86-13332617868 (Jane) / +86-17620152277 (Eric)

Email: hcy518@163.com (Jane) / sale2@dgdechuang.com (Eric)

Office Address: Room 2103, Building 8, Vanke Center, No.1 Changqing South Road, Chang’an Town, Dongguan, China

Factory Address: No.6 Shukeng Street, Yanwu Village, Dalingshan Town, Dongguan, Guangdong, China

Factory Address: No.6 Shukeng Street, Yanwu Village, Dalingshan Town, Dongguan, Guangdong, China